Tuesday, December 22, 2009

Think Customer - Cell Phone Addition

Wednesday, December 16, 2009

Work Order Integration, the Sequel

Check it out at www.YouTube.com/AcmeBiotech or at the Process Automation Usability Project.

Tuesday, December 15, 2009

Grab a Bucket of Popcorn...

Monday, December 14, 2009

One Stop Shopping

Sunday, November 29, 2009

SharePoint and the iPhone

Tuesday, October 20, 2009

Be Careful What You Ask For...

Dawn Marruchella, DeltaV Batch Marketing Manger, sent me this user suggestions link for Emerson Process Management. I thought I'd pass it along to everybody - http://www.userideas-emerson.com/

Monday, October 19, 2009

Surfin Safari

Here's just another reason to run out and get yourself an iPhone or iPod Touch:

Thursday, October 15, 2009

DeltaV in HD

- Layout files can be created for specific workstation names just like the Usersettings.grf files. Save the layout file with the name [workstation]_Picture.layout and it will only be applied to the matching workstation name. The workstation name restrictions are the same, so no dashes are allowed and use underscores with care as they tend to prevent customized user settings files from loading. You also won’t want to start a workstation name with a number even though DeltaV will allow it in DeltaV Explorer.

- If you have any errors in your layout file the entire file will be skipped. If what you get isn’t even close to what you expected there is probably an error and the default layout file was used instead.

- A custom layout file overrides settings that are common between the layout file and the user settings file. Since the layout file specifies initial graphics, toolbars and alarm banners the ones that load are those in the layout file, regardless of what is in the user settings file.

- In a multi-monitor system the layout file can be used to change what monitor is used for what purpose. For example, in a quad-head system monitors are numbered 1 through 4 by the operating system. The default layout makes monitor 2 the primary display (behaves the same as a single monitor system) and monitor 3 the secondary display (behaves like the second monitor on a dual-head system). Monitors 1 and 4 are defined as “user” monitors and are pre-defined for alarm list and alarm filter graphics by default. To rearrange the monitor usage without changing cabling (some furniture makes it difficult to get to after everything is installed) you can change the [MonitorAllocation] section (commented out initially).

- To add an additional picture to the layout definition you must make three changes. First, change the value of “Count.” This is the total number of pictures that are defined in the layout file. Don’t forget to decrease the value if you remove a picture. Second, add a “Picture#=” line that has the relative path to the graphic and graphic name without the extension. The base path is assumed to be the Pic folder of the workstation. Third, add a section that has the relative path and graphic name inside square brackets. This section will have entries for the screen, picture type, upper left corner position (X & Y coordinates), height and width.

- Easy trip-up prevention tip – if you change the picture name in the “Picture#=” line, don’t forget to change the name farther down in the file where the name is in square brackets.

- Picture height and width values don’t have to match the actual graphic that will be displayed. The graphic will stretch/shrink to fit the defined space reserved by the height and width numbers unless that functionality has been disabled for the graphic. This will require some testing to make sure all the displays you have defined or that may be switched to will appear correctly in the reserved area.

- Picture widths may not be what you expect. On a test system at 1920x1080 resolution, the alarm banner and toolbar widths needed to be set to 1914 instead of 1920 to display without extending onto the other display. Test often and try making minimal changes between tests.

Thursday, October 1, 2009

Going Bolding at Emerson Exchange 2009

So for the first time in a process automation system, there’s a tool to monitor the quality and predict the endpoint of a batch based on a PCA/PLS developed model. He implemented a really cool technique call Dynamic Time Warping (beam me up, Scotty) which is based on logic used in voice recognition software to remove the time variation in batch to batch runs in developing the models.

Through a presentation layer making use of Microsoft Silverlight, operations and engineering personnel can then monitor, via Internet Explorer, the progression of a batch in real time and not only identify deviations, but quickly determine if the variations will effect the overall batch quality based of critical quality parameters.

Monday, September 28, 2009

Emerson Exchange 2009 – Charming

Sunday, September 27, 2009

Emerson Exchange 2009 Preview

I don’t want to steal any of the thunder about what folks are going to see tomorrow from Emerson, but I thought I’d a least post the updated DeltaV logo:

More to come from Exchange over the next several days – stay tuned…

Monday, September 21, 2009

Numatics/DeltaV Integration

We have it connected up on one of our DeviceNet segments and have one of the solenoids connected up to a Crane Saunders diagram valve with a conventional switchpack. We used our standard valve module template in DeltaV, but instead of the output going directly to the solenoid, it goes to a register input within the Numatics.

We then constructed some logic, using function blocks available in the Numatics, to provide local interlocking based on another discrete input (a make-believe tank high level switch). One more switch allows us to turn the Numatics logic on and off, so comparisons between it and DeltaV can be demonstrated.

This puppy if FAST. I’m in the process of putting together a video I hope to upload to the Process Automation Usability Project website sometime after Emerson Exchange. We also constructed a valve sequence within DeltaV and ran it as fast as we could, simulating the valves around the bowl of a centrifuge. We then put the same logic in the Numatics and using another register, triggered the sequence from DeltaV. We actually had to slow the sequence in the Numatics down just so we could see it!

Friday, September 11, 2009

I have, on the other hand, been following a few folks to try and figure it out and hopefully pick up some useful information – honestly, I’m not just lurking.

Along with my engineering and management responsibilities, I dabble on the sales side of automation and have been introduced to the concept of the “elevator talk”. Either Jim Cahill or Mike Boudreaux, on one of their recent twits (is that what they're called?), provided a link to a blog (which provided another link to another blog) on the topic of the “customer’s elevator rant”, a prequel to the elevator pitch. It’s very enlightening, and a must read in preparing for the upcoming Emerson Exchange.

Hey, good news – in getting the hyperlinks to include in this post, I think I’ve made a small breakthrough in my twitter adventure. Maybe I’m not too old for this stuff after all. Ready to check me out - click here.

Wednesday, September 2, 2009

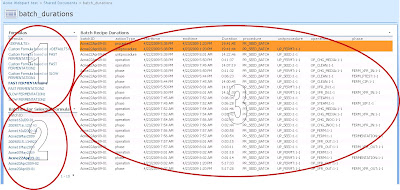

Data View Web Part, Part II

So we’ve put together a really good Batch Duration example. It’s a combination of 3 data view web parts, feeding each other in series. The first data view allows the selection of a formula, which populates the second data view with a list of batches that meet the formula criteria. By clicking on a particular batch id then populates the third data view showing durations. We even took advantage of the web part to highlight durations that exceed a fixed amount of time. Great for doing batch to batch comparisons.

Wednesday, August 19, 2009

Data View Web Part

In the screenshot below, I’ve used the web part to display data from a stored procedure, showing recent batches run on our demo system. The web part has the ability to highlight values or whole rows based on expressions. In this case, I’ve highlighted batches whose duration has exceeded a predetermined limit. Makes it easy to quickly identify the outliers.

Of course, it would be really neat if I could just click on the Batch ID in the list and get access to a report or launch a tool like History Analysis…

Monday, August 17, 2009

SharePoint As An Automation Dashboard

SharePoint is SQL based, so it’s SQL aware, almost SQL friendly. And since DeltaV has lots of stuff stored away in SQL (batch data, Syncade data, alarms and events data), this seemed like a good place to start.

First thing though, you’ve got to have Microsoft Office SharePoint Designer. The good news, it’s now free from Microsoft (Bill Gates must have been feeling especially generous one day). Click here to follow the link to the download site. You’ll want to get a good book on Designer and SharePoint (I’m still looking for one).

The specific tool we’ve been experimenting with is the data view web part. So to get a summary of orders from Syncade, you create a data source into the DMI_EBR database, looking at the vOrders view:

Thursday, August 6, 2009

A Prolific Comment

When a pharmaceutical company representative remarked “We’re awash with data, but we have no information”, Alison Smith of Aspen Technology she commented “this was a very apt statement. It applies to any environment in which technology has been deployed in the absence of an information design…”

Data to information, information to knowledge – a holistic approach to the application of S95 is key to keep all those thousands of terabytes of data from gathering electronic dust.

Tuesday, July 28, 2009

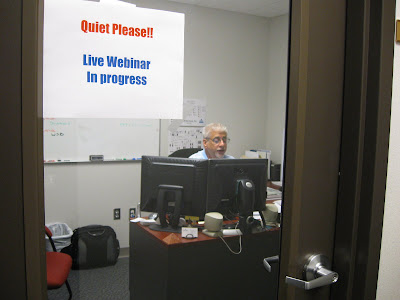

Webinar Series for SA Customers

Our goal is to provide helpful insight in our product and technology offerings and to help our Service Agreement customers get the most out of their systems.

I hosted the inaugural Webinar just this morning and we had excellent attendance from throughout the Carolinas.

Friday, July 17, 2009

Batch Events Whitepaper

Thursday, July 9, 2009

PMBR

Process History View just doesn’t have the horsepower for the types of queries required. And that’s OK, because the Event Chronicle is a SQL database. So what I’ve done is link the alarms and events table into Access. This was easy because the ODBC data source is already setup for you in DeltaV:

Then I created two queries – one to get unique Batch ID’s and one to get the batch events. The Find Unique BatchIDs query looks like this in SQL:

SELECT Right(Events1!Attribute,Len(Events1!Attribute)-InStr(1,Events1!Attribute," ")) AS BatchID

FROM Events1

GROUP BY Right(Events1!Attribute,Len(Events1!Attribute)-InStr(1,Events1!Attribute," ")), Events1.Attribute

HAVING (((First(Events1.Attribute)) Like "@*") AND ((Count(Events1.Attribute))>1));

Executing this gives:

PARAMETERS BatchID Text ( 255 );

SELECT Events1.Date_Time, Events1.State, Events1.Desc1, Events1.Desc2

FROM Events1

WHERE (((Events1.Attribute) Like "*" & [BatchID])) OR (((Events1.Desc1) Like "*" & [BatchID]))

ORDER BY Events1.Date_Time;

When I run the query, I get prompted for the BatchID:

The pressure drop data was captured with the LOG EVENT function in the FERM_PTEST phase.

So here's a way to generate some simple batch reports without dealing with those pesky EVT files. Head over to my website - I'll be consolidating the 3 posts about batch events/reports into a whitepaper.

Batch Events in PHV

One of the first things to note is the Parameter column contains both the unique Batch ID as assigned by DeltaV and the Batch ID as entered from the Create Batch view. The State column gives you a taste of the different “major batch events” now being captured. Here’s a non-comprehensive list of major batch events:

BATCH ADDED

BATCH REMOVED

CAMPAIGN CREATED

LOAD

Manual Phase Started

Mode Change

Operation Finished

Operation Started

Operation Started with Equipment

Phase Finished

Phase Started

Phase Started with Equipment

Procedure Finished

Procedure Started

REMOVED

Resource Acquired by recipe

Resource Released by recipe

State Changed

Unit Procedure Finished

Unit Procedure Started

Unit Procedure Started with Equipment

Noticeably absent from the list are report parameters. If I could somehow get report-like parameters into PHV, I’d have some pretty useful information. Enter the LOG EVENT function. The LOG EVENT function has been around a long time (go to BOL on how to use it), but the cool thing is how it looks in PHV. And it looks different, depending if it’s used in a regular module as opposed to phase logic:

When it’s used in just a regular module, the Desc1 column is empty. When it’s used in phase logic, the Desc1 column contains the Batch ID!

So for this example, if I look at the Parameter column to contain Acme11May2009 or the Desc1 column to contain Acme11May2009, and sort the result by Date/Time…to be continued.

Monday, July 6, 2009

Transitional Analysis and PAT

So check out www.transitionalanalysis.net for more information about the application. And by the way, the customer I was talking to doesn’t have a DeltaV system. He does have a bunch of chromatography skids with proprietary (vendor supplied) method controls. The TA application is platform agnostic.

Thursday, July 2, 2009

Become a Fan

If you’re a regular reader (or even if you’re just a lurker) become a follower. Now, you won’t be getting any discount coupons for MX controllers, but you’ll be letting everyone know you’re part of something bigger.

Tuesday, June 30, 2009

Keeping Focus

I got a call yesterday from one of my customers who’s just upgraded to version 10.3 of DeltaV. In case you haven’t heard, Emerson has equipped the new versions of control and recipe studio with Microsoft’s ribbon technology (ala Office 2007).

So Ray asks me “how do you know which control studio session has focus”? I hadn’t looked that close at 10.3 yet, but from past experience, the title bar at the top of the window is usually darker if that window has focus:

So I open up 10.3, launch three control studio windows, put them next to one another and damn if you can’t tell which one has focus:

Not a show stopper, but something to watch out for (BTW, the CS window in the upper left had focus).

Tuesday, June 16, 2009

Another 10.3 Nugget

Case in point – Linker utilities have been added to the batch toolbar to make linking the ActiveX buttons and lists in DeltaV Operate easy. Prior to version 10, a little under the hood magic was required to tie the objects together.

Just mouse over the buttons in the DeltaV Batch toolbar and you’ll notice the 3 new linker utilities:

Select the linker of your choice (below is the batch list control linker).

Be sure to select the linker after you’ve dropped the two items to be linked on the graphic – otherwise, you won’t be able to select them and complete the operation.

Wednesday, June 3, 2009

Shareware Behavior

“Behavior as used in computer science is an anthropomorphic construct that assigns ‘life’ to the activities carried out by a computer, computer application, or computer code in response to stimuli, such as user input. Also, ‘a behavior’ is a reusable block of computer code or script that, when applied to an object (computer science), especially a graphical one, causes it to respond to user input in meaningful patterns or to operate independently”

Out of the RA (Recipe Authoring) box you get some behaviors as part of Syncade. You also get a nifty Behavior Editor program for developing your own. As part of our in-house development work with Syncade, Scott Thompson came up with a clever new behavior to generate an email REM_SIMPLE_EMAIL.

You could conditionally notify a supervisor his attention is need – based on events. You could generate the status of an order, from inside the order, to folks who aren’t normally monitoring the batch. You could automatically notify your local business partner to dispatch a site services engineer because of an equipment or instrumentation failure.

I think there’re so many uses, I’ve posted the behavior up on the acmebiotech.com web site and made it available as a shareware, as-is download. Follow this link to the page for both the behavior and detailed instructions.

If you like it (or hate it), tell Scott and I about it.

Monday, June 1, 2009

Remote Terminal Sessions with Monitor Spanning

Version 10 now supports spanning monitors of DeltaV Operate on a remote terminal session. So for instance, if you connect to a remote session from any old PC with a couple of monitors attached, DeltaV Operate is smart enough to automatically give me a dual head session.

There are a couple of caveats:

- The monitors have to be in the horizontal configuration

- The maximum horizontal pixel width is 4096

The pixel width limitation means you can have 2 widescreen monitors side by side, or 3 1280x1024 monitors, or 4 1024x768 (but nobody uses that anymore, right?).

So you’re asking “Quick, tell me how to do this!” – It’s pretty easy. Most folks are familiar with the Remote Desktop Connection dialog box:

The thing is, there’s this /span option, and it’s not a selection as part of the Desktop dialog box. To use it, you need to use the mstsc command prompt. After creating the above .rdp file, you create a .bat file with the mstsc command:

By double clicking on the .rdp file, you get a single monitor session. Double clicking on the .bat file, you get a double wide!

Wednesday, May 27, 2009

Kit Bashing a DCS

And while the conversion van business has been around for a long time and has done well, I can’t say the same for the DCS “kit bashing” I’ve seen. Four times now I’ve had customers get caught in one of these “better” mousetraps, kit bashed from various control systems. The integrators don’t have a dog in the fight so it’s really easy for them to blame, after the fact of course, the hardware platform or system level software.

So the options to the end user are usually to do a major rewrite or hope and pray that hardware platform enhancements (faster processors, more memory) will somehow come to the rescue.

Be wary of someone pitching a DCS agnostic package that will have the same look and feel whether you use, for example, DeltaV or a SLC 5/05. Chances are if it sounds too good to be true, it probably is.

Friday, May 15, 2009

UGOC 2009 Day 2

One of the big hits during the product showcase was Dick Beverly from Emerson ASCO Numatics showing off their line of smart valve manifolds/remote IO. And I do mean smart. Not only do they handle analog and discrete signals in addition to the manifold outputs, talk all the major busses including Foundation Fieldbus and Ethernet, but their DeviceNet version supports a DeviceLogix module, allowing high speed (5 ms) function block or ladder logic.

I’m excited about now being able to offer a one stop shopping controls and automation solution. For example, handling high speed valve sequencing around the bowl of a centrifuge in addition to all the other required skid batch automation is now possible as part of a total Emerson solution.

Thursday, May 14, 2009

UGOC 2009 Day 1

One of this year’s cool attractions is the Emerson Wall – it’s a 20 foot long PlantWeb dreamscape with enough eye candy to keep folks coming back. Al Lee and Gordon Lawther from Emerson are here to put it through its paces.

Thursday, May 7, 2009

Cold Enough For Ya?

So now there’s a new drop down menu on the Controller tab of a controller node for additional selections of Cold Restart. "Always Disabled" is really no different than setting the timer to 0. "Enabled Within A Time Limit" allows you to set the time (no difference than now). The new choice is the "Always Enabled (maximum time)" selection, just in case being without power for more than 30 days just isn’t long enough.

Wednesday, April 29, 2009

Documentor 2.0 Goes Global – SharePoint Gets an Upgrade

Who knew a single Procedure could have over 3000 recipe parameters? So keep those cards and letters coming (actually, any and all opportunities for DeltaV Phase and Recipe documentation). Check out the Documentor 2.0 product datasheet at http://www.acmebiotech.com/Documentor%202.0%20Data%20Sheet.pdf

We were cutting edge (well, at least I think we were) when we started using SharePoint for our project collaboration sites. And while these sites have been highly successful and well appreciated by our customers, we’ve been using the same underlying platform (WSS 2.0) for 4 years now.

So I’m pleased to say that we’ve taken the first step in upgrading one of our servers to Windows SharePoint 3.0. Even though Microsoft has made SharePoint Designer (the replacement for Frontpage) available free of charge, some of the customizations I’ve been able to do in the past just aren’t possible with the new SharePoint version.

But that’s not to say there aren’t some really cool features – a Gantt chart view is available, built in to the Task list. The available 3rd party web parts is quite impressive, many available free of charge. And lots of them use Microsoft’s Silverlight technology, including some impressive charting web parts for dashboard components.

Check out http://www.codeplex.com/, Microsoft’s open source project hosting site.

Monday, April 20, 2009

Batch Events and 10.3

So one of the first one’s I was excited about was the ability of the batch executive to have “significant batch events” flow to the event chronicle. And while I’m sure OSI is happy about this one, everyone should be.

Let’s be clear as to what “significant batch events” are – it’s NOT everything that’s currently in the batch journal, but all events associated with creating, starting, ending, and unloading of procedures, unit procedures, and operations get to the event chronicle.

Note in the screenshot below how the batch ID is displayed – you get both the ID entered by the operator and the internal ID DeltaV uses for tracking in the historian:

Launch the Batch Application manager, and on the Batch Executive tab, select the Advanced tab, then select the Configuration Settings tab – here you’ll find all sorts of BE trivia selections. Scroll down to the Enable Alarm and Events Journaling, and double click it:

Tuesday, April 14, 2009

PAT, QbD, and the ISA

I’ve taken a keen interest in all things PAT related (I’ve written about this before), because I truly believe we folks in the automation industry can provide the technological muscle, hard and soft, for the pharma and biotech industries.

So I was really pleased by the cover story of the March issue of InTech magazine from the ISA titled “If you build it in …”

http://isa.org/InTechTemplate.cfm?template=/ContentManagement/ContentDisplay.cfm&ContentID=74790

It brought into the mainstream of process control and automation the challenges and potential rewards of PAT in providing better process understanding. This understanding translates into increased yields, shorter production cycles, less “bad batches”, and ultimately, lower manufacturing costs.

And I guess there’s somewhat of the proud grandfather complex in me (thanks, Larry Wolfe), but checkout the section in the article labeled “Real-time quality by design” and Talecris Biotherapeutics in Clayton, NC. The water system monitoring and control described was our first DeltaV installation at Talecris and has been one of early PAT wins by any company in the industry. While some of the innovative principles have moved on (Joydeep Ganguly is now at Biogen Idec and Gerrit Vogel is back in the Bayer family), Phil Culberson continues to drive innovation at Talecris as they expand the PAT and QbD concepts, leveraged by their use of DeltaV.

Saturday, March 14, 2009

Abstract Submissions

Hey, don't forget to submit your abstract for the 2009 Emerson Exchange - it's due this Monday, the 16th of March. Visit www.emersonexchange.org for more information.

In the current economy, it's a great way to increase your chances of getting to go to Orlando this fall.

Friday, February 20, 2009

In 30 years...

They had this one where a guy is shaving with a new, innovative, 3 blade razor. The first one gets most of beard, the second gets what the first one missed, and the third one gets what the second one missed. The final tag line was “…we gave you 3 blades because you’ll buy anything…” But here we are, 30 years later, and a 4 blade razor gives me the best shave ever.

So what’s that got to do with anything? Quad-head monitors, that what. I don’t get it. Dual-head monitors, I get – I think their great, best thing ever. Quad-heads, no way. Way too much real estate for a single keyboard and mouse, especially if you have to react or acknowledge something quickly. Doesn’t matter whether it’s 2 over 2 or 4 in a row. I don’t like them.

And in 30 years, I’ll have a nine head monitor setup without a keyboard or mouse – I’ll just think it and it’ll show up…

Tuesday, February 10, 2009

Linkedin Groups Lame?

Maybe it’s a sign of the times, but almost all the discussions are headhunters offering up career opportunities. Now my sampling is certainly not statistically valid, but I find it annoying.

I’m sorry, but I really want technical based discussions in these technical groups. Aren’t there enough venues on the web for headhunters?

Monday, February 9, 2009

Sync With Syncade

Syncade (Emerson Process Management’s Smart Operations/MES suite) is a great collection of modules for Material Management, Order Management, Equipment Tracking, Training and Development, Document Control and Archiving, etc.

And while it’s tightly integrated with DeltaV’s batch engine, it needed a little help when it comes to tying non-batch processes and events to its suite of modules.

So that’s where Sync With Syncade comes in – it bridges the real-time world with the transactional one. OPC flags are used to trigger events associated with equipment in the ET module. These events can then cause workflow to automatically begin.

The cool thing about Sync With Syncade is that it installs on an OPC server – anyone’s OPC server. The communication to Syncade is handled by a web service call.

This was our first implementation using web services – definitely more to come.

You can check out the product data sheet for Sync With Syncade here.

Tuesday, January 13, 2009

New Automation Forum

I've known Tim Alosi of New England Controls for many years now. And in the spirit of out with the old and in with the new, Tim is overhauling his old DrTim site into www.ControlDoctors.com. Check out all the different control and automation offerings. Don't forget to sign up for some of the different forums.